Virgtucky, OK

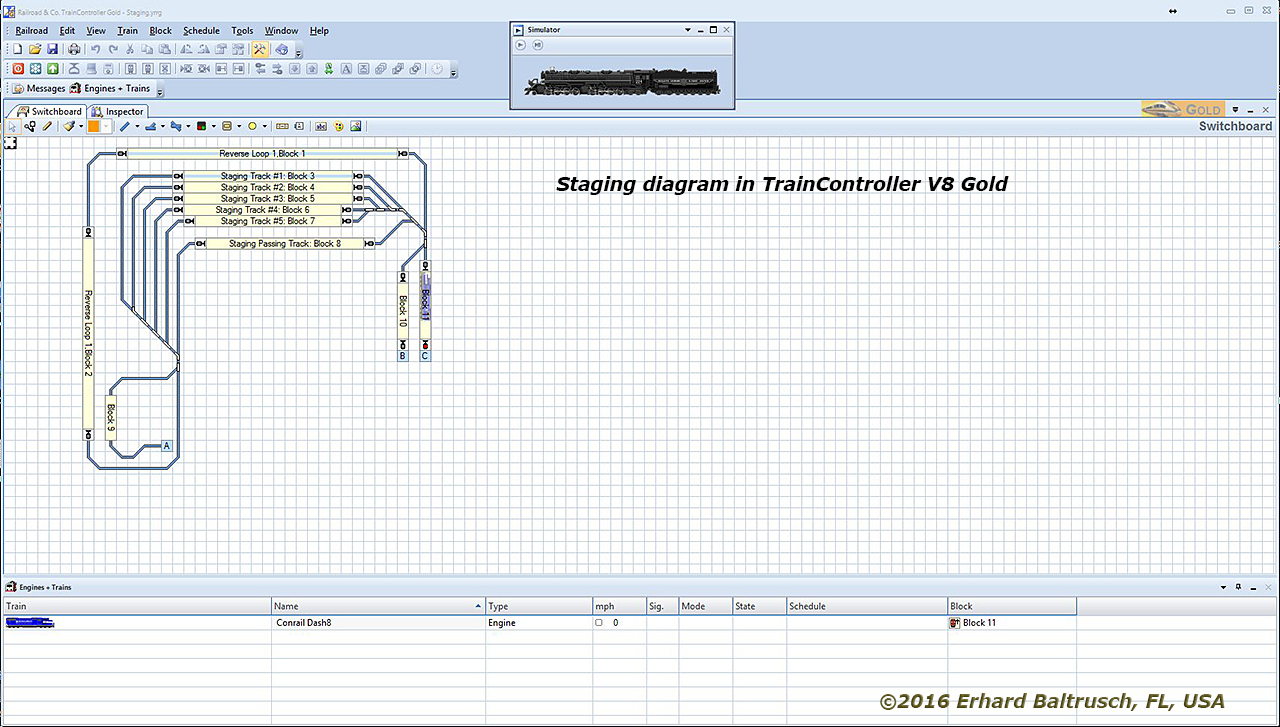

This H0-layout is loosely based on Richmond, VA and Paintsville, KY, hence the name "Virgtucky". It is a DCC controlled layout (NCE system) which can also be controlled by computer using TrainController® software.

So far, 4 trains can run simultaneously on this 24 ft by 14 ft layout with 1 additional train running under manual control.

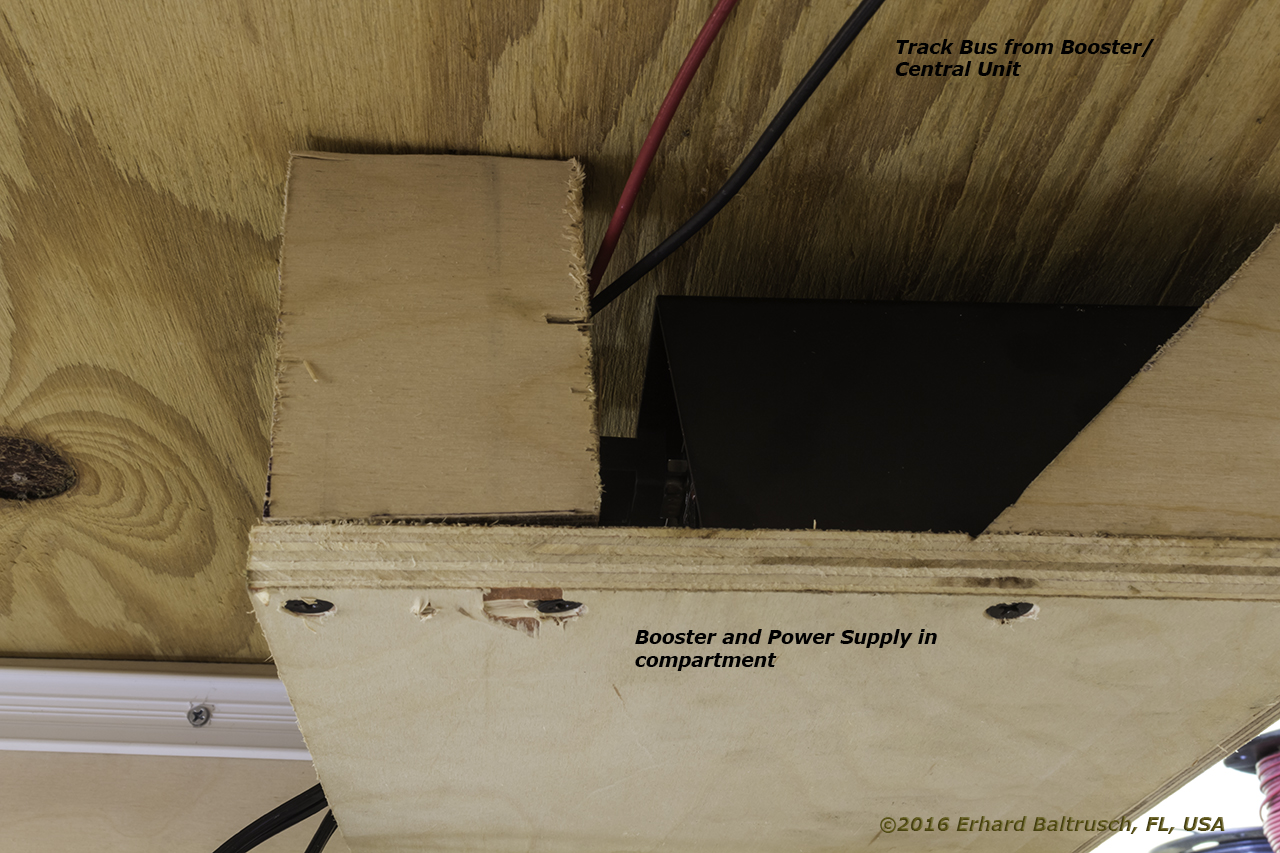

To supply enough power, each district has its own booster, plus there's one extra booster for a separate accessory bus. This way, a short circuit in one district does not affect any other power district.

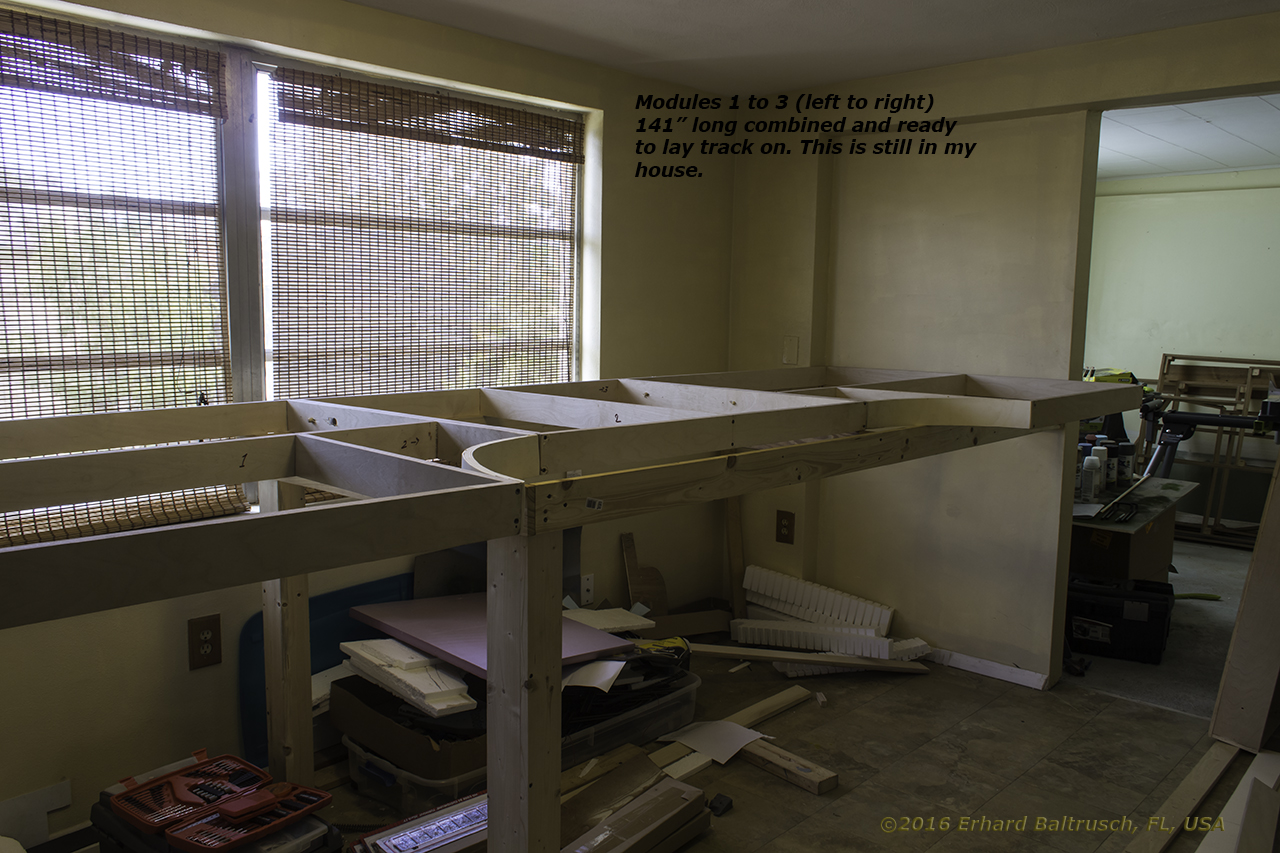

The main benchwork components were built in our shop and hauled to OK where they were assembled and completed to compensate for eventual discrepancies in measurements.

In this case, the customer wanted to build scenery by himself. We were to deliver the benchwork with track laid and functional electronics.

March 2016

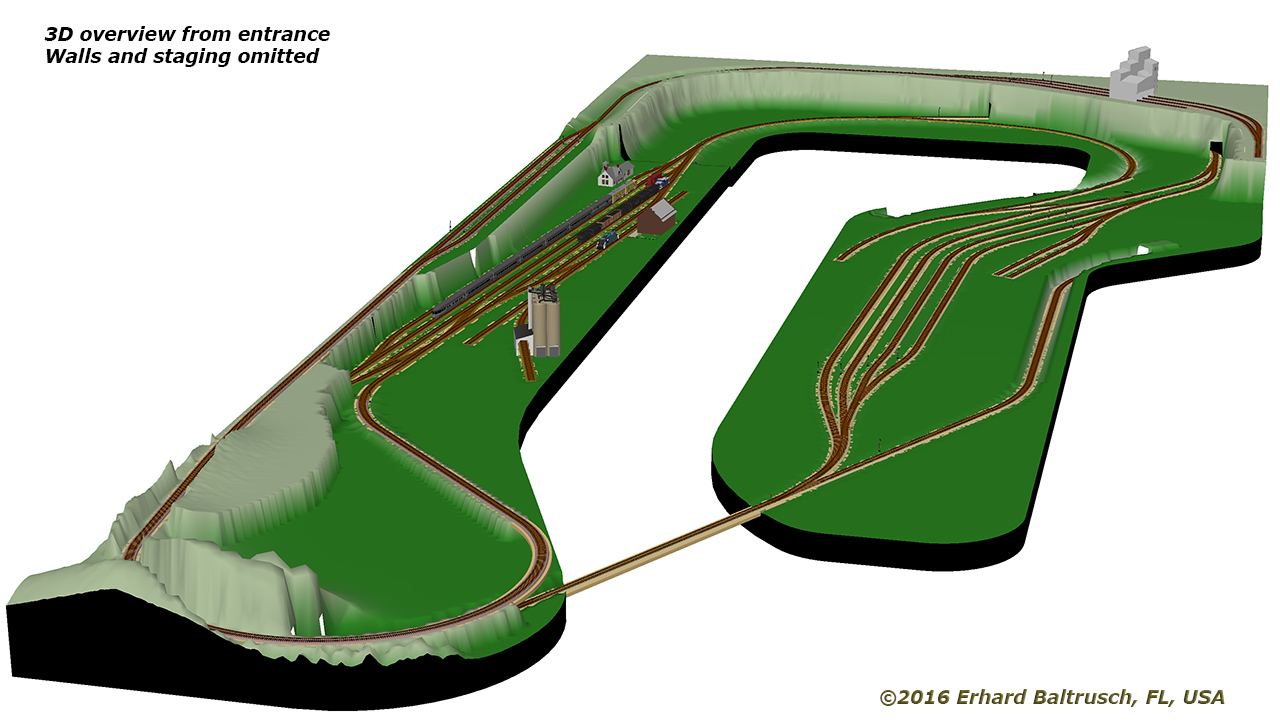

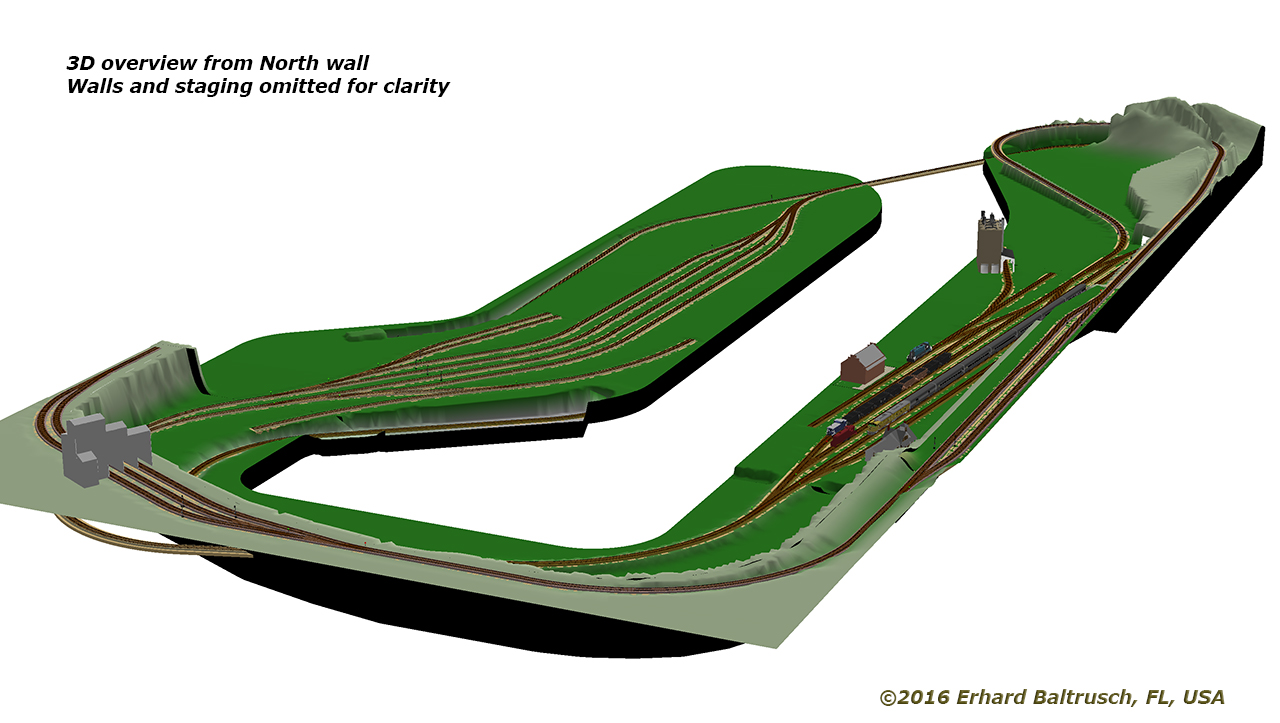

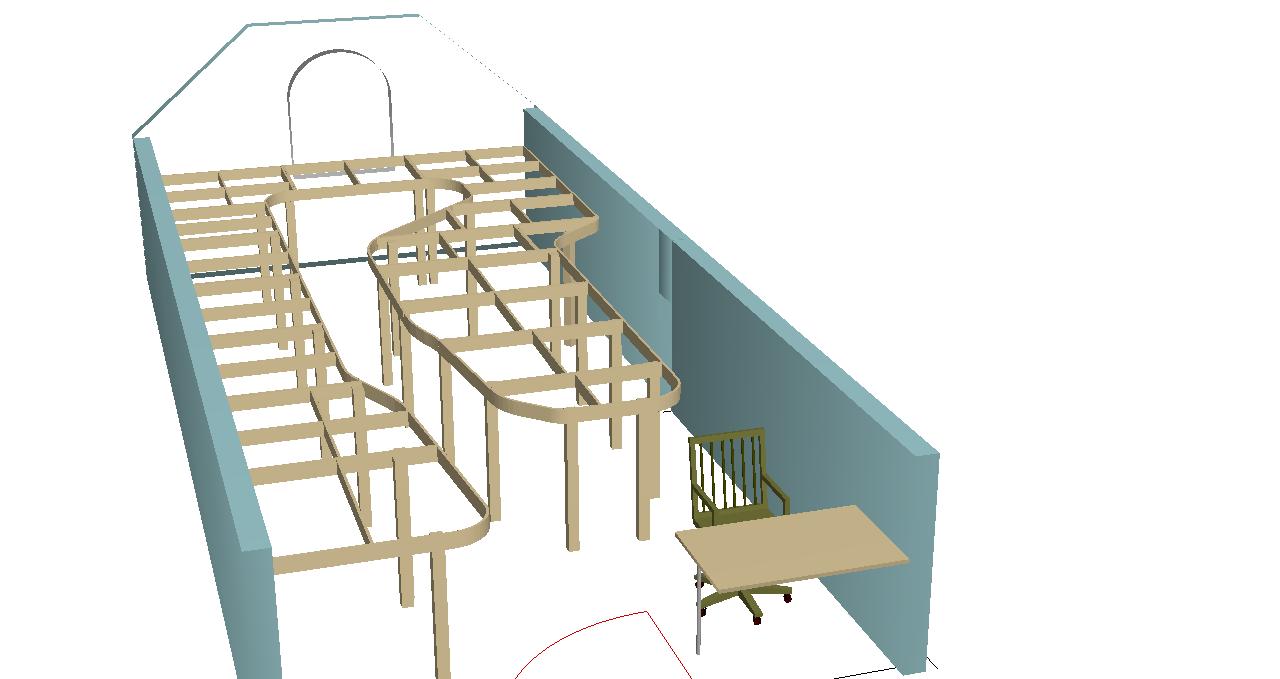

Planning started early March, 2016. Here are some renderings:

3D-rendering seen from the entrance.

3D-rendering seen from the north wall.

3D benchwork rendering.

The actual layout room.

06-03-2016

Actual work started in June, 2016.

Go to top10-20-2016

In October more modules were ready to be hauled off.

Go to top01-03-2017

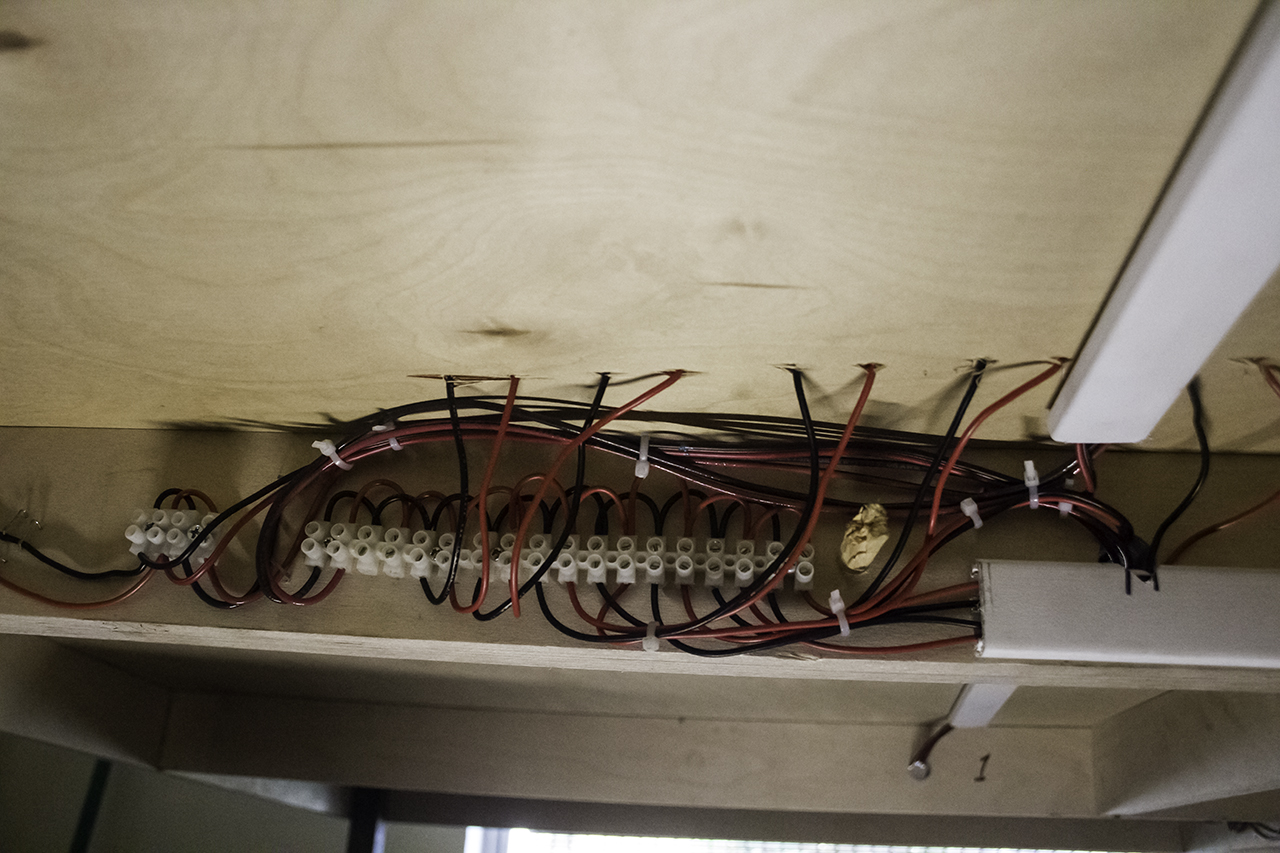

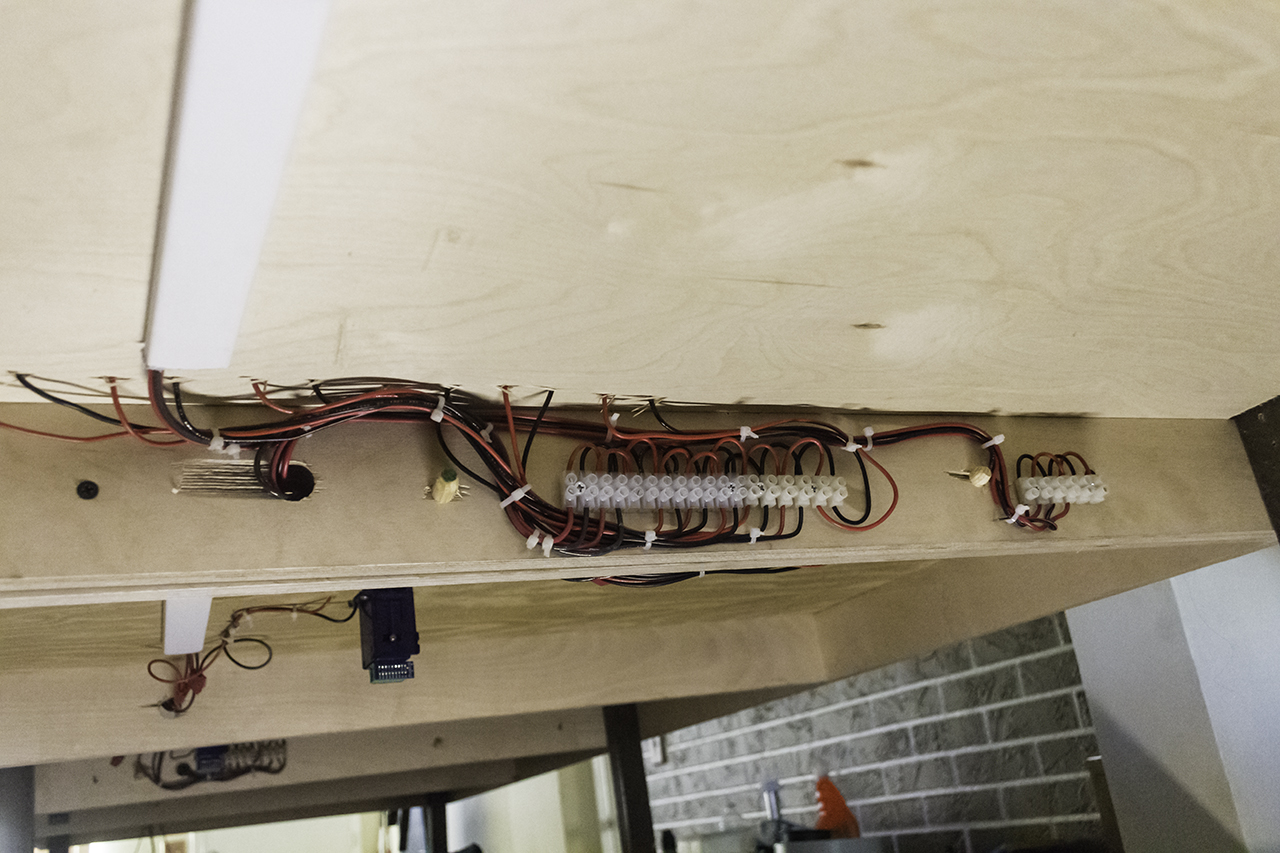

Still wiring the layout in January, 2017

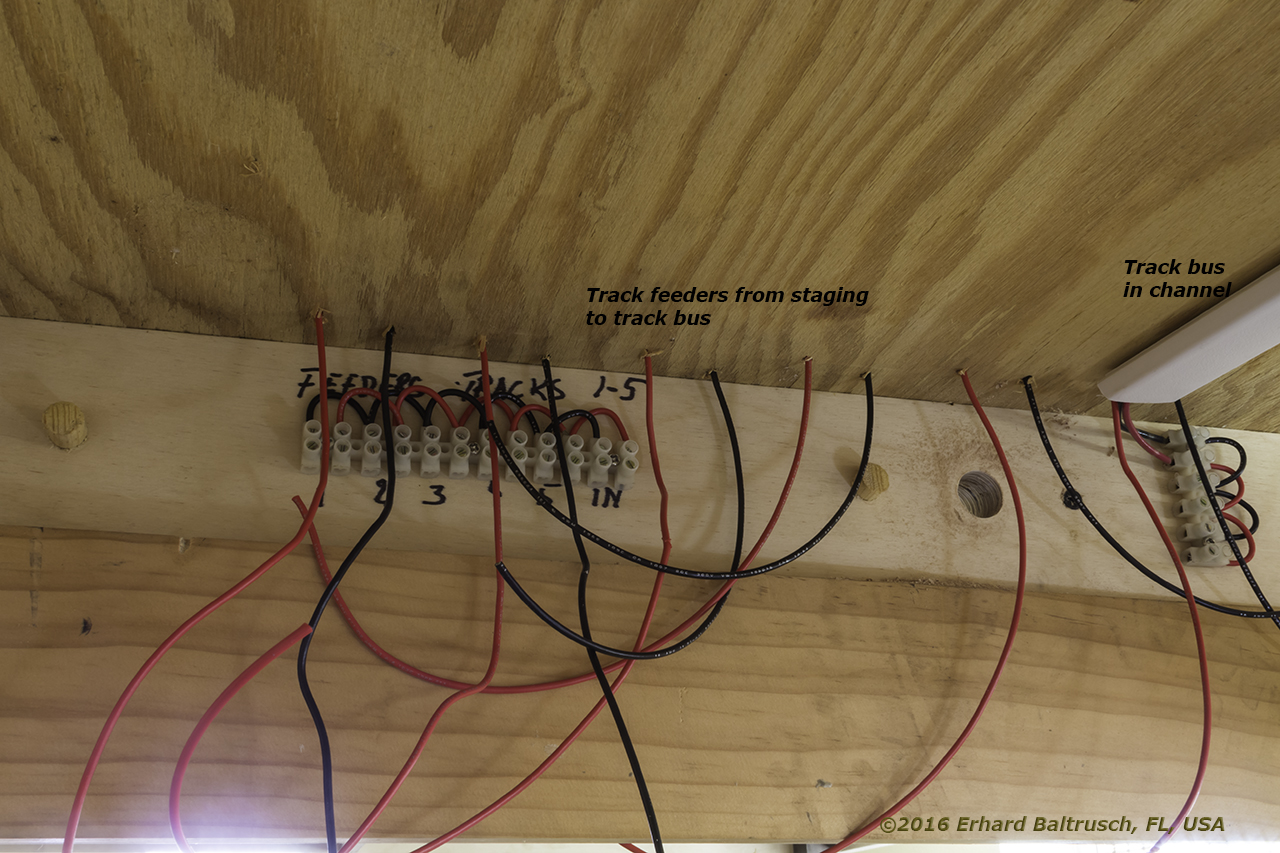

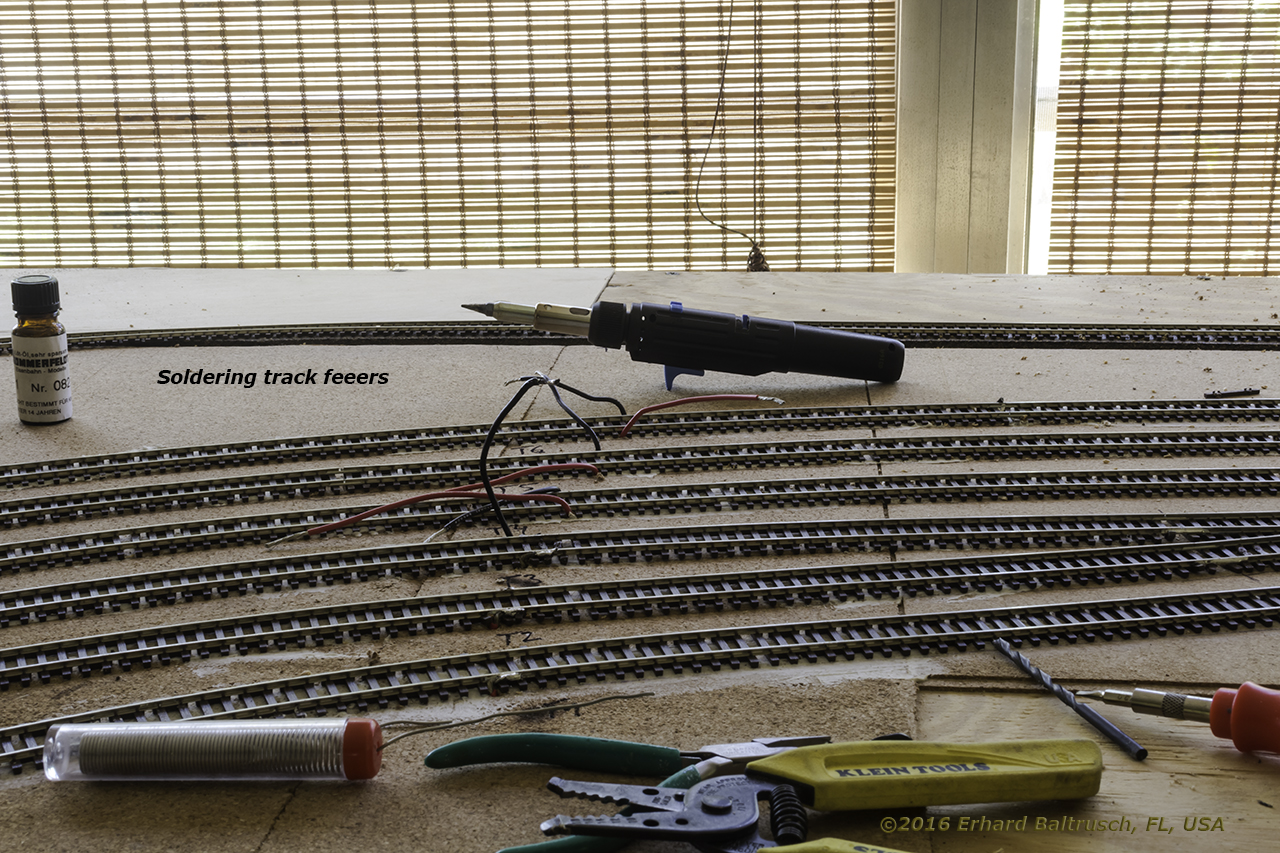

Staging track feeders and occupancy sensors, as well as an automatic reverse loop module had to be wired in.

04-12-2017

Finally we're in Oklahoma setting up the finished modules. Turned out that they fit snugly into the given space - only minor adjustments needed.

Go to top11-11-2017

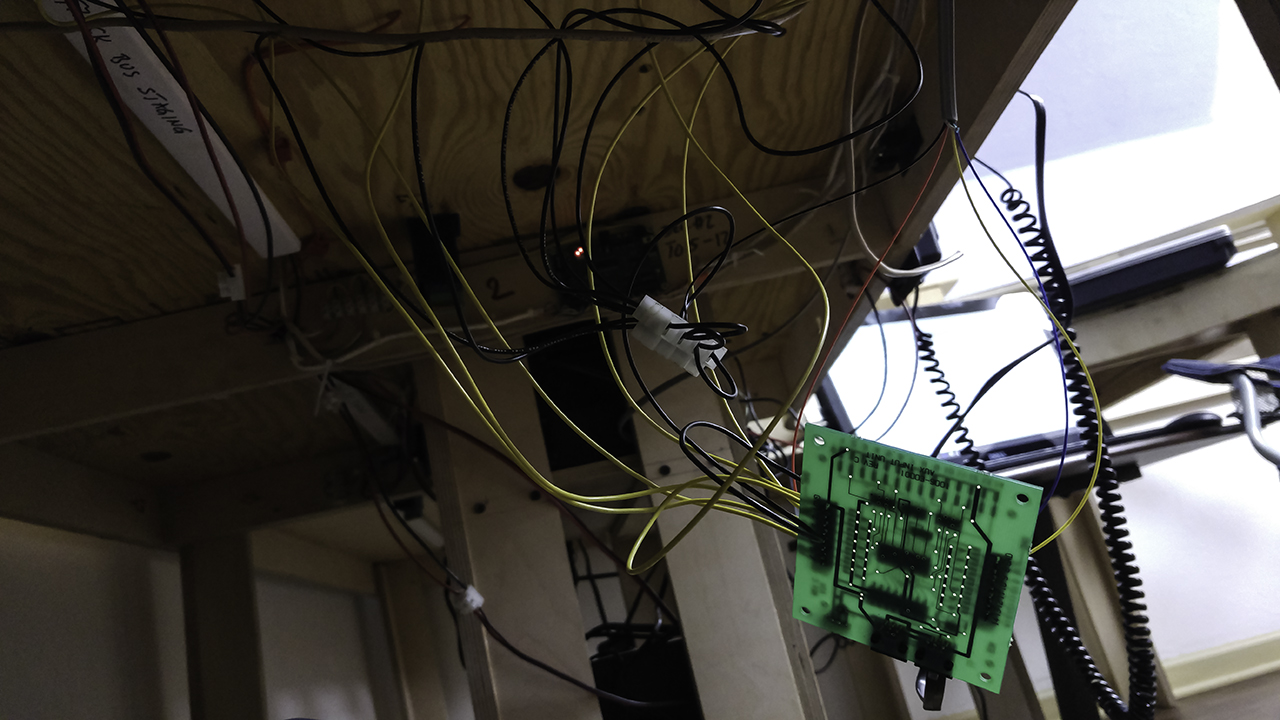

Our next stint in Oklahoma was in November for the tasks of more wiring and teaching the customer some basic scenery techniques.

The wring pictures were taken before tidying up this "spaghetti bowl" of wires hanging around...

Go to top02-25-2018

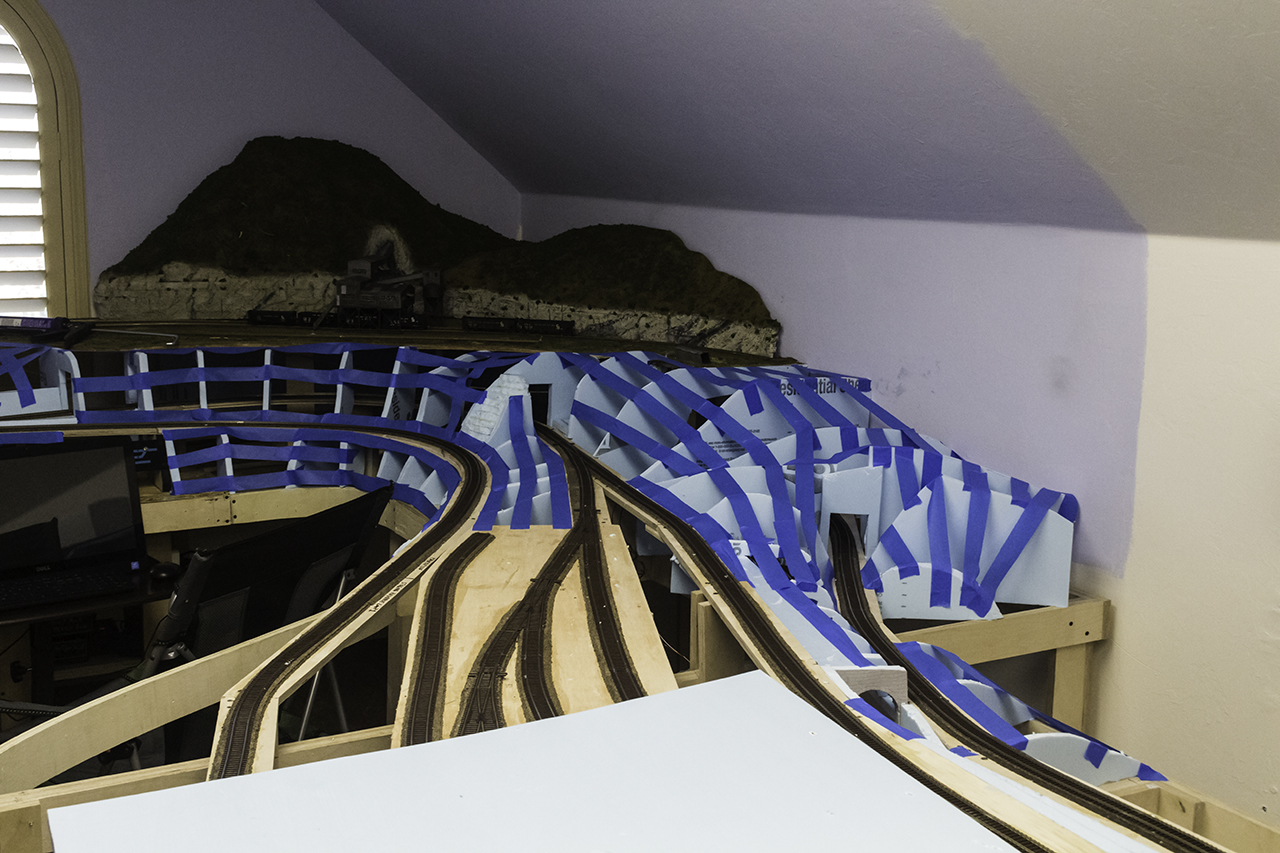

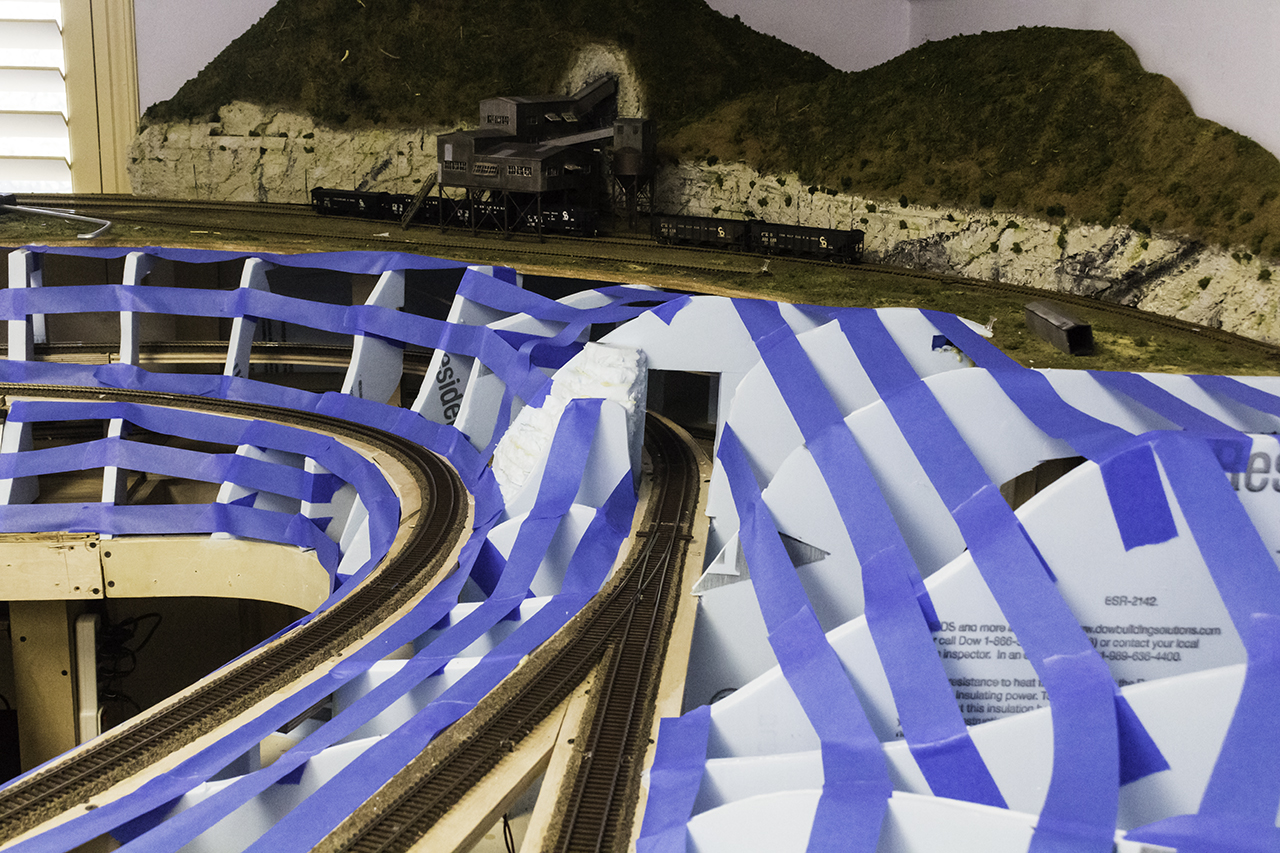

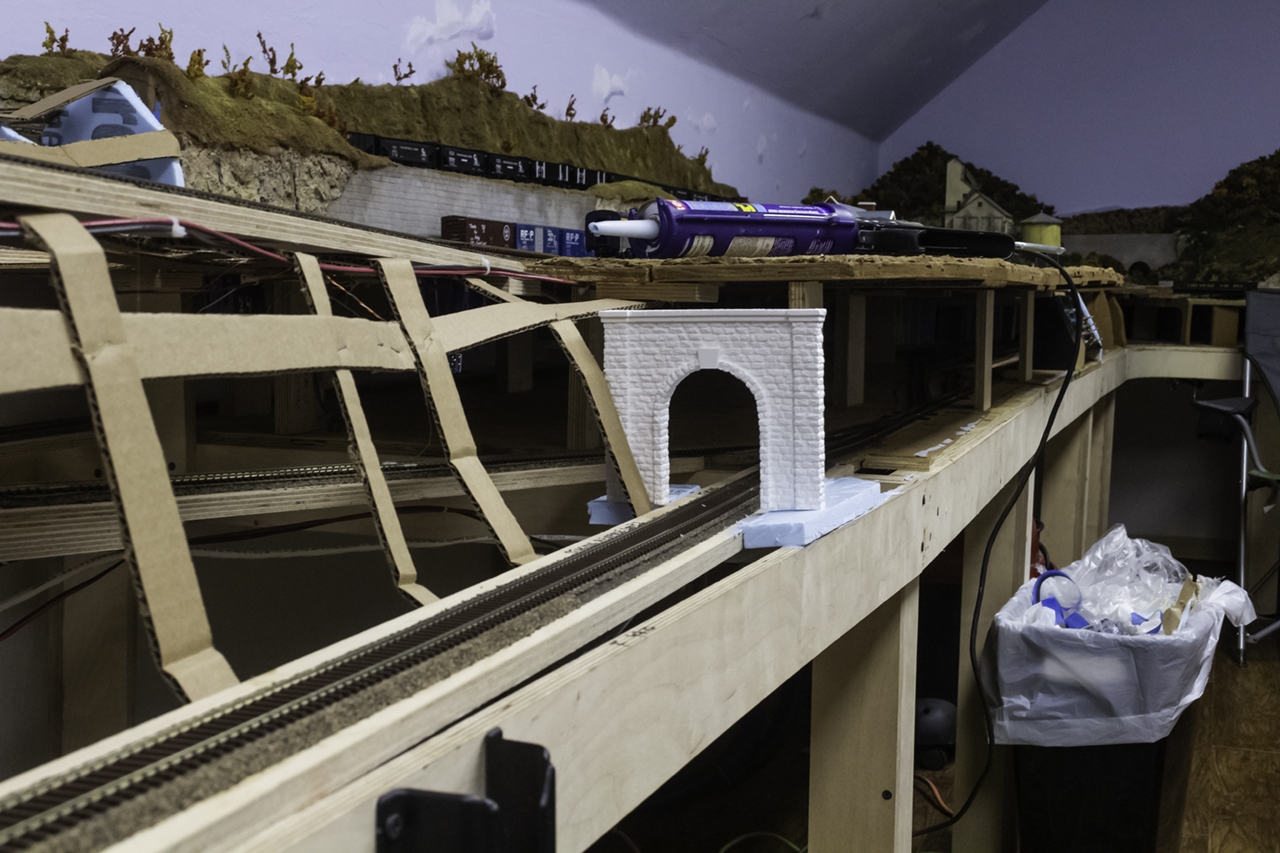

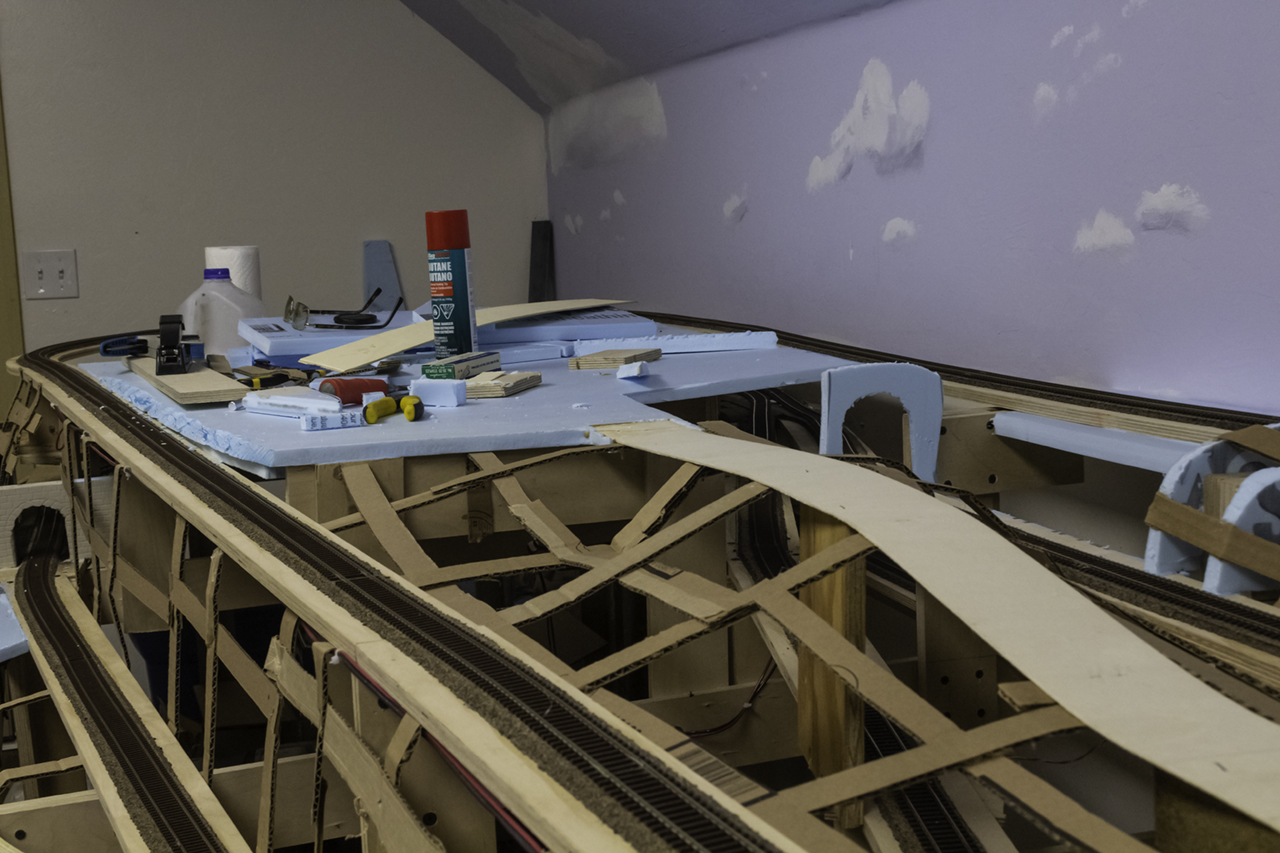

In the meantime the upper deck has been finalized laying track and a ton of more wiring was done. I like to call this session the "Blue Tape" stint as we had to create all the scenery profiles from extruded foam abd blue painter tape.

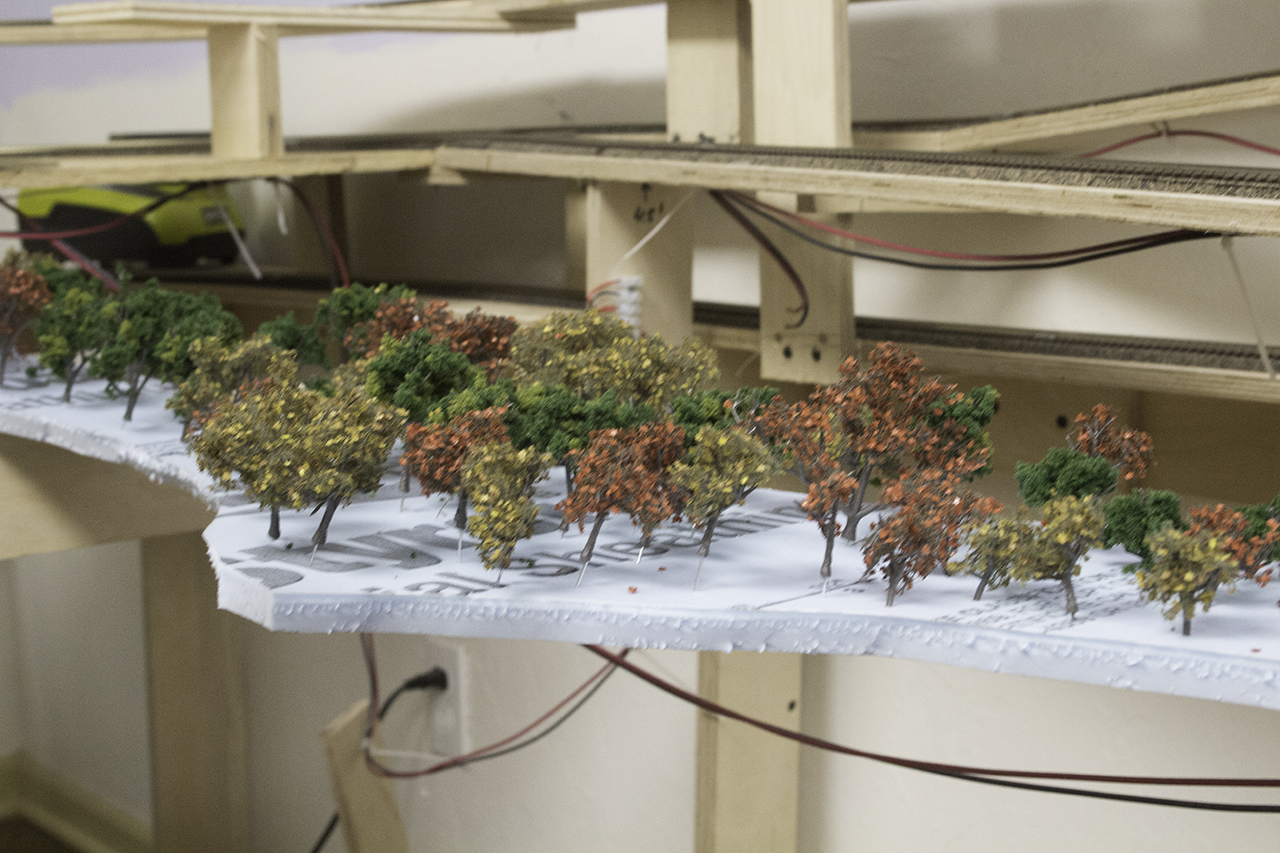

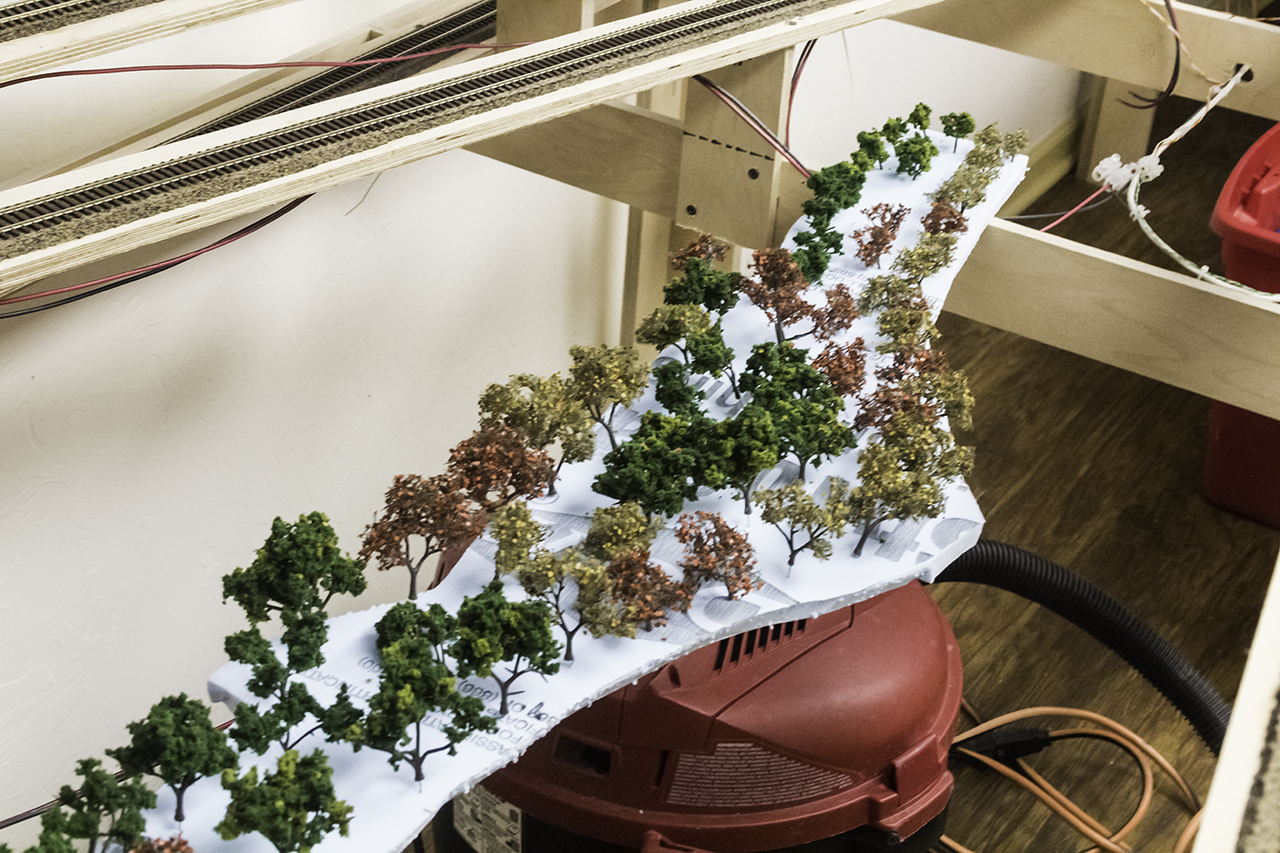

The customer tried his hands on doing scenery on a removable piece for the future coal mine and I have to give him him kudos for his work. Nice job for a newbie!

Go to top06-25-2018

In June more scenery was done by the customer and we were up in Oklahoma again to configure the controlling software, i. e., entering data into the program's database, as well as configure the customer's engines to run at prototypical speeds.

01-17-2019

I visited a friend in Texas in January, 2019 and on my way back home decided to take a little detour to Oklahoma to see how the layout there was coming along. A lot more scenery was done, however, more scenery was still needed near the room entrance area.

Go to top01-18-2019

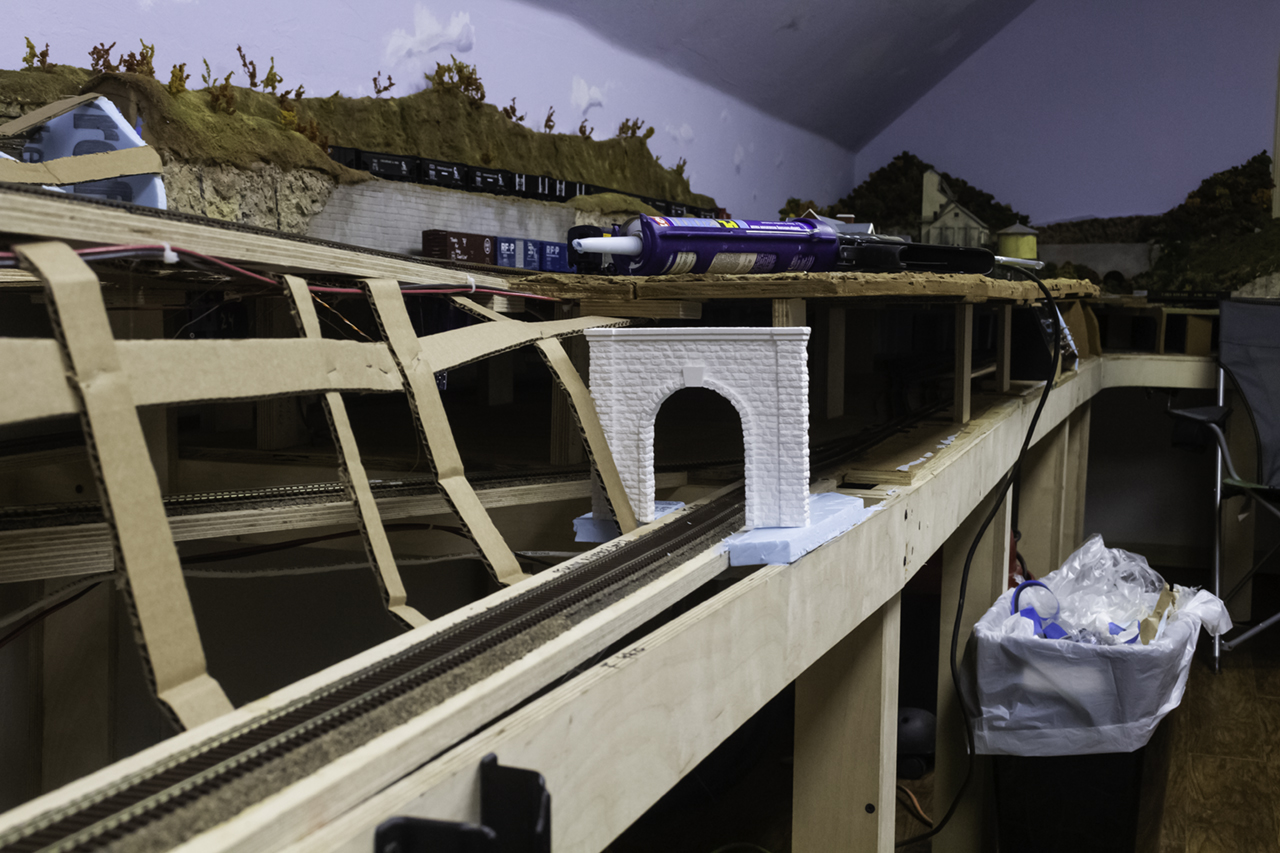

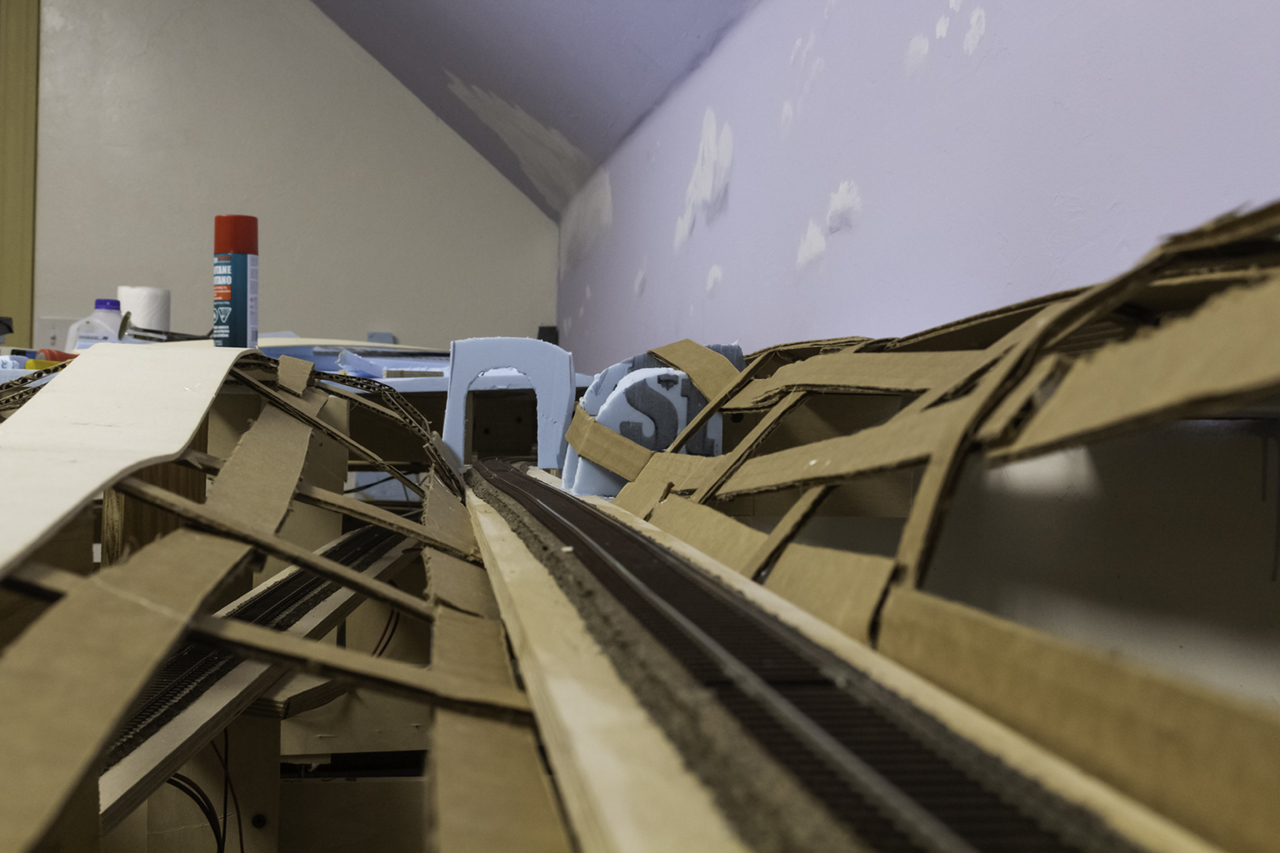

The next day I took care of the scenery support for the entrance area. This is a simple cardboard strip webbing which will later be covered with soaked plaster gauze and plaster of Paris. Then the rock faces will be carved and painted.

Go to top07-21-2019

Today the customer sent me some pictures about the progress he made on his layout. He experimented with 3D-clouds made of cotton and the town of Paintsville now has a connection to the depot, even with bus service. It also seems that a power company moved in to light up the city at night.

Go to top01-21--2019

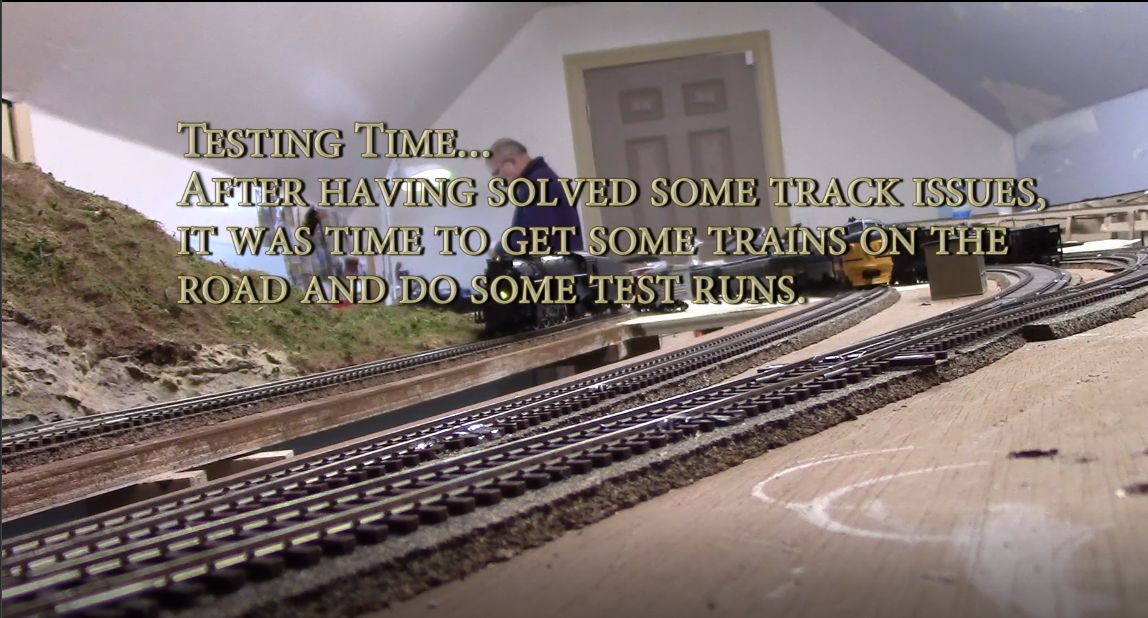

Here's a short video clip featuring test runs before we left for Florida:

Go to top